DALLAS — You have probably never heard of the Holcim plant in Midlothian, but it is a crucial part of development projects in D-FW. And it is doing something different that could eventually impact the entire world.

The Midlothian plant produces cement. In case, you have always used the terms interchangeably, you should know, producers of cement say it is like the flour in a cake recipe. Once mixed with other ingredients, it becomes a batter that is used to produce a cake—which would be the concrete in this metaphor.

And producers have been using the same "cake" recipe for a long time, says Holcim Senior Vice President of Cement Sales Patrick Cleary.

"We have been doing the old Portland cement recipe for 100 plus years. And now, we are looking to rapidly change the way we construct…change the way we build," said Cleary.

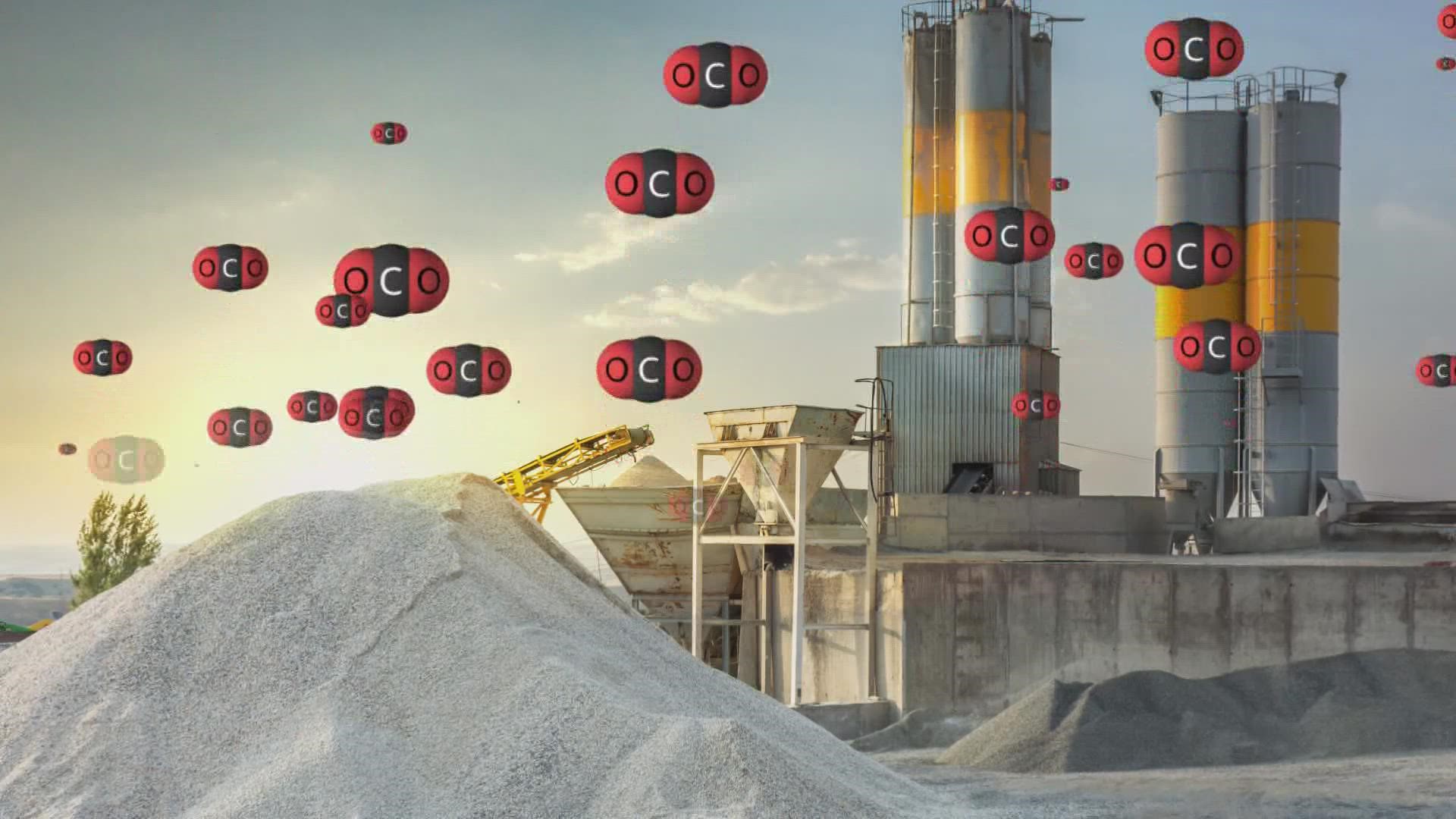

Cleary said his industry recognizes it needs to make big changes. If you didn't know, cement produces a lot of the greenhouse gas carbon dioxide. Making a pound of cement produces .9 pounds of CO2, according to cement.org. That happens because of a reaction when the components of cement are super-heated.

"We don't hide from it. Cement manufacturing is a large contributor to CO2. But we also have a huge opportunity to be a huge part of the solution," said Cleary.

Cleary said not only is his company the largest cement producer in the U.S., they're also, "The first ones to announce a net zero pledge -- net zero by 2050."

To become carbon neutral, they have moved to a new kind of cement, called OneCem.

Holcim said because it includes “up to 15% per ton of finely ground high quality limestone”, it produces about 10% less carbon dioxide than typical cement.

Holcim is transitioning its 14 U.S. plants to this product, including Midlothian, which is, "The first plant in the country to do this transition."

A 10% reduction in carbon dioxide is modest. But multiply that by the two million tons of cement Holcim produces in Midlothian each year, and the change starts to add up.

“We have to look at taking a baby step at first, but we can’t slow down the acceleration," said Cleary.

Cleary said the company is already working on the next mixture that might produce a 30% CO2 reduction. So, Cleary said, this is the first of many steps to cleaner concrete.

And that concrete is already being used in some parts of North Texas.

“You won’t even be able to see it, in fact, we already have nearly a million tons of this cement in concrete today in and around the Dallas-Fort Worth market," said Cleary.

Some of the places where he said this new cement product has already been used: The PGA headquarters in Frisco, the new Prosper High School, and some I-35 paving projects.

One last note: The Holcim plant was damaged in the February winter storm, which greatly impacted the supply of concrete mix in North Texas. In fact, months after the storm, some builders said they couldn’t even get enough to pour one complete new home foundation. Cleary said the Holcim plant is now operating again at full speed.